Friction and wear reduction by graphene nano platelets for hybrid nano Aluminium matrix composite under dry sliding conditions

DOI:

https://doi.org/10.30544/536Keywords:

friction; wear; self-lubrication; nano aluminium matrix composite.Abstract

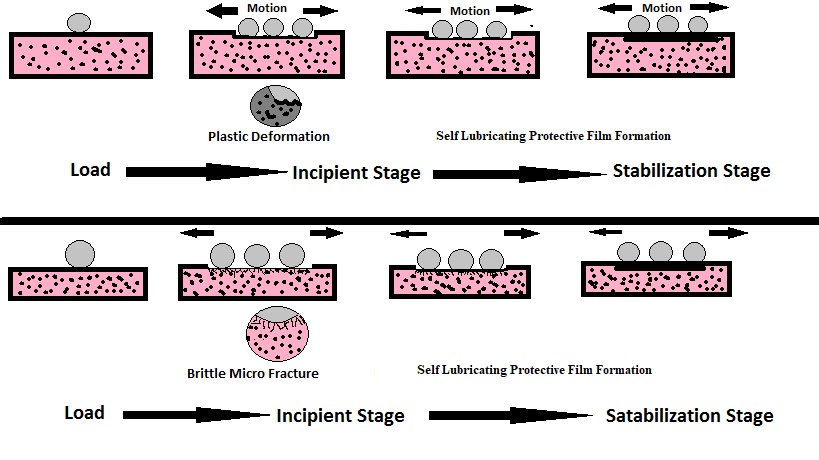

Friction losses and wear losses are the main failure reasons in the internal combustion (IC) engine components i.e., cylinder liner and piston. So, it demands lightweight self-lubricating low friction and wear-resistant materials to increase the efficiency and reduce the emission issue of the IC engine. In this concern, tribological tests are performed on self-lubricating aluminium composites samples reinforced with 6 wt.% of γ-Al2O3 and Graphene Nano Platelets (GNP) with varying concentration (0.5 wt.% - 5 wt.%), using ball-on-disc tribo-configuration under dry sliding conditions. The scope of this study is to investigate the anti-friction and anti-wear properties of GNP as reinforcement in the hybrid nanocomposite. The hybrid nanocomposite samples are fabricated using Spark Plasma Sintering (SPS) fabrication route. From the results, it is reported that friction and wear reduction percentage is 37.43 % and 51.64 %, respectively for the hybrid nanocomposite with 5 wt. % GNP. It is attributed to the inclusion of GNP, which reduces the Coefficient of Friction (COF) and improves wear resistance of the composite significantly.

References

K.S. Prakash, P. Balasundar, S. Nagaraja, P.M. Gopal, V. Kavimani: Journal of magnesium and alloys, 4 (2016) 197-206.

A. V. Muley, S. Aravindan, I.P. Singh: Manufacturing Review, 2 (2015) 15.

S.C. Tung, M.L. McMillan: Tribology International," 37 (2004) 517-536.

P.D. Srivyas, M.S. Charoo: JurnalTribologi, 25 (2020) 83-101.

P.D. Srivyas, M.S. Charoo: Materials Research Express, 6 (2019) 125702.

P.D. Srivyas, M.S. Charoo: Materials Today: Proceedings, (2020).

D.B. Miracle: Composites science and technology, 65 (2005) 2526-2540.

A. Evans, C. San Marchi, A. Mortensen: Composites in Industry (2003) 9-38.

J. Singh, A. Chauhan: Journal of Materials Research and Technology, 5 (2016) 159-169.

H. Ye: Journal of Materials Engineering and Performance, 12 (2003) 288-297.

M. Chen, T. Perry, A.T. Alpas: Wear, 263 (2007) 552-561.

J.U. Ejiofor, R.G. Reddy: Jom, 49 (1997) 31-37.

K.M. Shorowordi, T. Laoui, A.S.M.A Haseeb, J.P. Celis, L. Froyen: Journal of Materials Processing Technology, 142 (2003) 738-743.

Z. Wang, L. Wu, Y. Qi, W. Cai, Z. Jiang: Surface and Coatings Technology, 204 (2001) 3315-3318.

H. Chandrasekaran, J.O. Johansson: CIRP Annals, 46 (1997) 493-496.

L. Pedersen, L. Arnberg: Materials Science and Engineering: A, 241 (1998) 285-289.

N. Roy, A.M. Samuel, F.H. Samuel: Metallurgical and Materials transactions A, 27 (1996) 415-429.

M. Elmadagli, T. Perry, A.T. Alpas: Wear,262 (2007) 79-92.

A.B. Gurcan, T.N. Baker: Wear, 188 (1995) 185-191.

J.I. Song, K.S. Han: Composite structures, 39 (1997) 309-318.

B. Yazdani, H. Porwal, Y. Xia, H. Yan, M.J. Reece, Y. Zhu: Ceramics International, 41 (2015) 9813-9822.

J. Llorente, M. Belmonte: Journal of the European Ceramic Society, 38 (2018) 3441-3446.

L.Y. Chen, H. Konishi, A. Fehrenbacher, C. Ma, J.Q. Xu, H. Choi, X. C. Li: ScriptaMaterialia, 67 (2012) 29-32.

A.D. Moghadam, E. Omrani, P.L. Menezes, P.K. Rohatgi: Composites Part B: Engineering, 77 (2015) 402-420.

Standard, A. S. T. M. (2010) G133-05.

V. Iliuţă, M. Rîpă, J. Javorova, G. Andrei: IOP Conference Series: Materials Science and Engineering, 174 (2017) 012015.

P. Kumar, M.F. Wani: Journal of Tribology, 140 (2018) 1-19.

A.T. Pérez, A.H. Battez, G. García-Atance, J.L. Viesca, R. González, M. Hadfield: Wear, 271 (2011) 2963-2967.

C. Georgescu, L. Deleanu, C. Pirvu: Mater SciEng, 147 (2016).

S.D. Heintze, A. Cavalleri, M. Forjanic, G. Zellweger, V. Rousson: Dental Materials, 22 (2006) 1051-1062.

S. Le Roux, C. Boher, L. Penazzi, C. Dessain, B. Tavernier: Tribology international, 52 (2012) 40-49.

M.C. Valigi, S. Logozzo, S. Affatato: Materials, 10 (2017) 548.

R.J.K. Wood, P. Ramkumar, L. Wang, T.J. Wang, K. Nelson, E.S. Yamaguchi, N. Otin: Tribology and Interface Engineering Series, 48 (2005) 109-121.

P. Heilmann, J. Don, T.C. Sun, D.A. Rigney, W.A. Glaeser: Wear, 91 (1983) 171-190.

S.L. Rice, H. Nowotny, S.F. Wayne: Wear, 74 (1981) 131-142.

P.D. Srivyas, M.S. Charoo: Journal of Tribology, (2020) 1-29.

Downloads

How to Cite

Issue

Section

License

Copyright (c) 2020 Pranav Dev SRIVYAS, M.S. CHAROO

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their published articles online (e.g., in institutional repositories or on their website, social networks like ResearchGate or Academia), as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

Except where otherwise noted, the content on this site is licensed under a Creative Commons Attribution 4.0 International License.

According to the

According to the