Development and characterization of hybrid coconut/glass fibers reinforced low density polyethylene composites for bumper application

DOI:

https://doi.org/10.30544/453Keywords:

Composite; coconut fiber; glass fiber; car bumper; low density polyethylene.Abstract

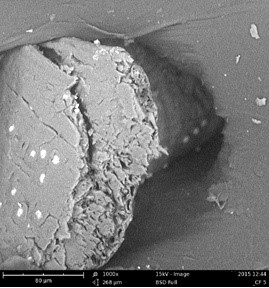

The EU's End of Life Vehicles (ELV) regulations are forcing car manufacturers to consider the environmental impact of their production and possibly shift from the use of synthetic materials to the use of agro-based materials. However, poor mechanical properties and certain manufacturing limitations currently limit the use of agro-based materials to non-structural and semi-structural automotive components. This research is focused on a composite of hybrid coconut/glass fiber as reinforcement in recycled low density polyethylene matrix alone to enhance the desired mechanical properties for car bumper as automotive structural components. X-ray fluorescence analysis conducted on coconut fiber showed the presence of silica and alumina materials make coconut fibre a choice one. Morphology analysis was performed using scanning electron microscopy (SEM), which reveals that there are small discontinuities and reasonably uniform distribution of the reinforcement fibers and the reinforced low density polyethylene (RLDPE) binder resulting to better mechanical properties. Physic-chemical properties that directly affect developed composite such as variation of Density, Water Absorption, Tensile Strength, Bending strength, Modulus of rupture, Impact Strength and Hardness Values were investigated for both unhybridized and hybridized developed composite. The study shows the successful development of composites of coconut fiber (CF) hybridized with glass fiber (GF) and reinforced low density polyethylene (RLDPE) binder using a simple molding technique. Hybridized samples (CF-GF/RLDPE) showed higher strength when compared to un-hybridized (CF/RLDPE) composites. Better microstructural bonding exists with 25% and 30% wt CF-GF composite resulting in good mechanical properties for the hybridized composites. The grades of composites obtained in the course of this study are applicable in the production of low strength car bumpers.

References

W. S. Arnold, I.H. Marshall, J. Wood: Composite Structures, 16 (1990) 85-101.

S. S. Cheon, J. H. Choi, D. G Lee: Composite Structures, 32 (1995) 491-499.

M. M. Davido, S. M. Sapuan, D. Ahmad, A. Ali, K. Abdan, M. Jonoobi: Journal, Materials and Design, 31 (10) (2010) 4927-4932.

B. P. Minaudo, J. Rawson, M. Montone: SAE Technical paper 970483 (1997).

C. L. Clark, C. K. Bals, M. A. Layson: SAE Technical Paper 910049 (1991).

B. Gilliard, W. Bassett, E. Haque, T. Lewis, D. Featherman, C. Johnson: SAE Technical Paper, 1 (1999) 10-14.

J. Rawson: SA Technical Paper 1999-01-1015 (1999)

M. N. Suddin, M. S. Salit, N. Ismail, M. A. Maleque, S. Zainuddin: Suranaree J. Science Technology. 12, 1 (2004) 39-45.

M. M. Davoodi: Elsevier Materials and Design, 29 (2008) 1447-1452.

ASTM D578 / D578M - 18 Standard Specifications for Glass Fiber Strands. Book of Standards Volume: 07.01

M. Sumaila, I. Amber, M. Bawa: Asian Journal of Natural and Applied Sciences, 2 (1) (2013) 39-49.

BS EN 319:1993: Particleboards and fibreboards-Determination of Tensile Strength Perpendicular to the Plane of the Board. The British Standards Institution, London.

Y. Zhang, Y: Elsevier Materials and Design, PR China, 27 (2006) 64-68.

C. G. E. Ping, N. Wang, C. Stephen, Y. Lu: Journal of Computing and Information Science in Engineering, 2 (2002) 141.

D. J. Andrea, W.R. Brown: W.R., (1993). Material Selection Processes in Automotive Industry, Michigan Transportation Research Institute, USA, 34.

R. Hosseinzadeh, M. M. Shokrieh, L. B. Lessard: Composite Structures 68 (2004) 419-427.

Downloads

How to Cite

Issue

Section

License

Copyright (c) 2020 Akinlabi O. David, Ibeh Stanley Chukwuemeka, Enegide E. Osther, Garba N. Salihu

This work is licensed under a Creative Commons Attribution 4.0 International License.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgment of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgment of its initial publication in this journal.

- Authors are permitted and encouraged to post their published articles online (e.g., in institutional repositories or on their website, social networks like ResearchGate or Academia), as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).

Except where otherwise noted, the content on this site is licensed under a Creative Commons Attribution 4.0 International License.

According to the

According to the